Inventor - 3D Annotations

So now you’ve learned how to use Model Dimensions (Blog – Model Dimensions vs User Dimensions) as opposed to manually adding User Dimensions to your drawing’s views. Now let’s take it another step, shall we?

More and more I’ve seen companies begin to embrace the ability to document the solid model within the 3D realm and use the 2D drawing as inspection documents.

All major dimensions, tolerances, notes, etc are input into the 3D model and that is sent to the machine shop as opposed to the drawing. Then the drawing is where the designer/drafter will manually add specific dimensions needed for inspection by QA. This is about as close to “going paperless” as I’ve seen companies get. This practice is nothing new per se, as I recall companies moving towards this back in the early 1990s

If you need management’s buy-in, show them the cost savings of not having to spend as much time doing 2D drawings that basically repeat the same information you already have in the model.

OK, so how do you do such?

You can add general annotations and notes to your 3D part model and/or assembly.

When in a part file, you use the Tolerance Feature command and the General Profile Note to add Geometric Dimensioning & Tolerancing (GD&T) as well as other needed manufacturing information to the model.

GD&T annotations on the 3D model describe the tolerances, controls, and allowable variation in the model. The term Model-Based Definition (MBD) refers to a fully defined 3D model. The annotated 3D model is often sent directly to manufacturing to create the physical part.

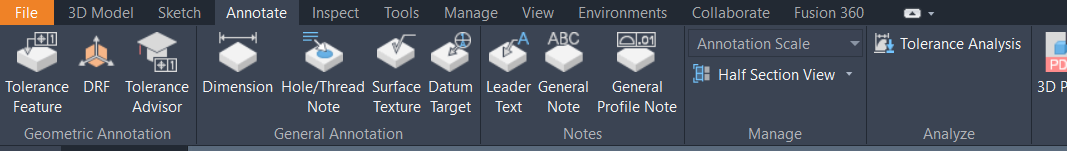

Use the Annotate tab on the ribbon menu when a part or assembly is open, to add the desired 3D annotations to the model:

Use the Tolerance Feature command to add GD&T annotations to your model. Use the Tolerance Advisor command to help understand the state of your model and manage the Tolerance Feature annotations:

3D annotation commands work just like drawing environment annotation commands.

Some tips and things to consider:

1. When you finish adding 3D tolerance annotations or tolerance features to your model, use the Tolerance Analysis to provide a summary and report of the stackup results. Allowing you to easily identify potential manufacturing issues and use the bi-directional associativity between your model tolerances and Tolerance Analysis to refine the tolerances. You can then perform iterations of the analysis to maintain the required quality while reducing cost.

2. Set the Select Annotations filter in the Quick Access Toolbar (QAT) to manage your annotations. The Select Annotations filter also supports the window selection and All in Camera command.

3. Changes to Document Settings Units tab do not affect the 3D annotations. Use the Document Settings Standard tab to specify the Active Standard to set the units. If no active standard is set the first time you use the 3D annotation command, you’ll be prompted to choose one.

4. The scale of your 3D annotations are independent of the Annotation Scale option in the Application Options > General tab. 3D annotations can also have a different size in each view. To set such, Right mouse-click the view in the browser and select the Annotation Scale to set the scale per the selected view:

You can also control the annotation scale of the active view by selecting the Annotation Scale drop-list in the Annotate tab > Manage panel. Use the Auto setting to let the system control the size or choose Custom to define a scale not available in the list.

*Some pictures and text taken from the Autodesk Knowledge Network